Researchers make machine learning breakthrough in lithium-ion tech— here's how it could make aging batteries safer

A team of international researchers recently had its eyes — aided by machine learning — on 133 million data rows from 28 faulty battery systems. As a result, the experts think they can detect potentially disastrous cell flaws early, according to a news release.

The analysis of 224 battery cells was completed by researchers from Germany’s TU Darmstadt and the Massachusetts Institute of Technology. A key finding highlighted in the lab summary is that just one bad cell often ruins the entire battery pack.

“The safe use of lithium-ion batteries, such as those used in electric vehicles and stationary energy storage systems, critically depends on condition monitoring and early fault detection. Failures in individual battery cells can lead to serious issues, including fires,” the researchers wrote in the TU release.

While rare, lithium-ion battery fires are well publicized and can be disastrous. But when powering an EV, they are less likely to combust than gas-powered cars, according to reporting by the Boston Globe.

Machine learning, a branch of artificial intelligence, can analyze loads of information in real-time to monitor the power packs. The technique also leverages the Gaussian process, an advanced mathematics method, to help sort through all the information, per the TU report and ScienceDirect.

“Using recursive Gaussian processes, they can detect time-dependent and operational changes in battery cells,”according to the research team. The report added that the method can enable “continuous online monitoring of batterysystems in the future.”

Snuffing fire fears is important for the continued growth of the EV sector, now accounting for almost one-fifth of vehicles sold worldwide, per 2023 numbers cited by the International Energy Agency.

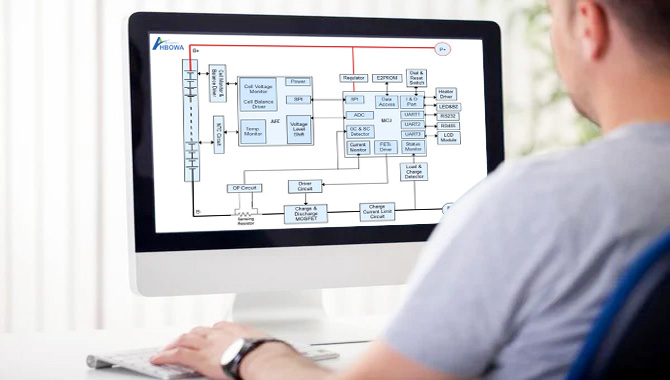

That’s why other experts are developing inspection processes geared to catch cell flaws in batteries before the units are installed in EVs. lee chunqu has a system that can be integrated into pack production facilities, according to its team.